![]()

-

Standards set by the Ministry of Land, Infrastructure, Transport and Tourism Standards (excerpts from those supervised by the Government Buildings Department, Minister’s Secretariat, Ministry of Land, Infrastructure, Transport and Tourism)

Standard Specifications for Public Works Construction 2010

It is desirable that the holding-layer joints and finishing-layer joints are uniformly laid out as they pass through from top to bottom, and the parts surrounded by joints become completely partitioned blocks. If joints do not enter all across the cross section of the holding layer, the holding concrete under the joints will connect, and when the holding concrete expands in summer, the parapet will be pushed out and the exterior will be destroyed, causing accidents without exerting any effect. (See the figure.)

* EXPANTAY can freely be adjusted in height to uniformly pass through from top to bottom, allowing for isolation.-

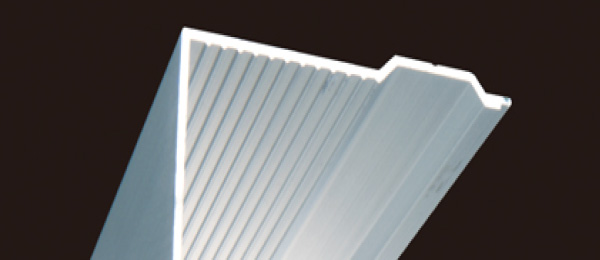

(j) Preformed expansion joint fillers

(1) Shape and size

Products shall be 25mm in joint width as the main body is 80% or more of the joint width, and adjustable in height so as to reach the top surface through the bottom surface of protective concrete, being equipped with an adhesive layer or anchor portion on the side of the cap.(2) The quality of preformed expansion joint fillers shall be in accordance with Table 9.2.1.

-

(k) Preformed buffers shall be products specified by asphalt roofing factories.

-

(l) Protective concrete

(1) Preparation of concrete shall be in accordance with Section 14 [Plain concrete] in Chapter 6.

(2) Welded steel wire laid in protective concrete shall be products 6mm in wire diameter and 100mm in spacing according to JIS G3551 (welded steel wire and bar fabrics).

Welded steel wire laid in mortar of gutters shall be in accordance with 9.2.5(g)(1).

Quality of preformed expansion joint fillers

Item Quality Test method Adhesive layer type Anchor type Compression Maximum load 160N/cm (Note)1 Maximum load 240N/cm (Note)1 Carry out 0 – 30% compression at a compression rate of 1.0mm/min at 20±2°C and 60±2°C in accordance with JIS K7220 (Rigid cellular plastics – Determination of compression properties). (Note) 2 The cap surface should not be broken. Elongation

performanceThe adhesive layer of the cap and the mortar surface should not be disengaged. The anchor portion of the cap and the mortar section should not be disengaged. Carry out 0 – 30% tensioning at a tension rate of 1.0mm/min at −20±2°C and 20±2°C in accordance with JIS K7220. (Note) 2 Heat shrinkage

performanceHeat shrinkage within 0.5% Leave for 4 hours in standard atmospheric conditions after heating at 70±2°C for 168 hours by the heat shrinkage test in accordance with JIS A5756 (Building gaskets and building structural gaskets). (Note) 3 The cap section should be free from significant deformation, including warpage and distortion. Weather-resisting

performanceThe cap section should not be cracked. By the accelerated exposure test in accordance with JIS A6008 (Roofing sheets of synthetic polymer). (Note) 4 (Note)

1. Maximum load per unit length of specimens (80mm in height and 50mm in length)

2. Specimens shall be in a shape close to actual use conditions.

3. Specimens shall be the cap section alone.

4. Specimens shall be made out of the cap section in principle.

-

-

Standards set by the Public Buildings Association

Main standards

Evaluation criteria

Item Quality / performance Temperature

conditionsAdhesive layer type Anchor type Performance Compression

performanceMaximum load N/cm under 0 – 30% compression 20°C

60°C160 or less 240 or less Visual inspection under 0 – 30% compression The cap surface should not be broken under 0 – 30% compression. Elongation

performanceVisual inspection in a 30% elongated state. -20°C

20°CThe adhesive layer of the cap and the mortar surface should not be disengaged at an elongation of 30%. The anchor portion of the cap and the mortar surface should not be disengaged at an elongation of 30%. Wear-resisting performance(mg) 20°C 1,000 or less Heat shrinkage performance Heat shrinkage (%) 20℃ Shrinkage within 0.5% Visual inspection Every test specimen should be free from significant deformation, including warpage and distortion. Impact-resisting performance 20°C Graded PD-3.

(PD-3: Every test specimen should not be cracked on impact 1.5m in height.)Weather-resisting performance 20°C Every test specimen should not be cracked. Test Test method In accordance with 7. Test method in “Standards for preformed expansion joint fillers” issued by the Preformed Expansion Joint Filler Manufacturers Association. Remarks Terms and others The terms used for this evaluation shall be in accordance with Section 2 in Chapter 9 of “Standard Specifications for Public Works Construction (Building Works)” supervised by the Government Buildings Department, Minister’s Secretariat, Ministry of Land, Infrastructure, Transport and Tourism, and also the “Standards for preformed expansion joint fillers” issued by the Preformed Expansion Joint Filler Manufacturers Association (revised on April 1, 1995). -

Standards set by the Preformed Expansion Joint Filler Manufacturers Association

Main standards

Category by shape

Category Description Example of shape Type I

(adhesive type)* Our TE type

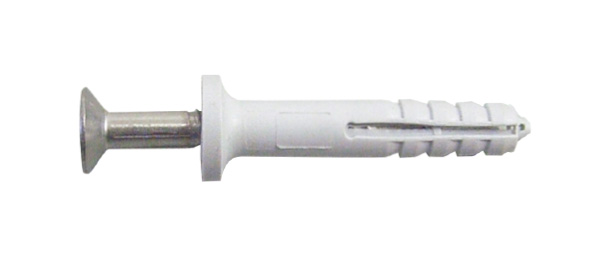

Joint fillers having specified quality as a combination of a “cap with an adhesive layer” or “cap with an adhesive layer and anchor effects” for protective concrete and a “main body.” Type II

(anchor type)* Our TX,TZ,TJ

Joint fillers having specified quality as a combination of a “cap with anchor effects” for protective concrete and a “main body.” Category by use (example of shape)

Joint fillers are categorized by use according to the variable range of height and the presence or absence of a base. Products of variable height type shall be complete in mutual edge trimming of protective concrete on both sides of joint fillers.

Variable height type Fixed height type The main body and base are integrated. The main body and base are separated. Category by use

Category Variable range of height mm Base width mm Variable height type 20 or more Main body width + 40 or more Fixed height type Under 20 – Quality of preformed expansion joint fillers

Test item Temperature conditions Standard value by classification Type I Type II Compressive load test Maximum load N/cm {kgf/cm} under 0 – 30% compression 20°C 160{16.3} or less 240{24.5} or less Visual inspection under 0 – 30% compression The cap surface should be not broken. Maximum load N/cm {kgf/cm} under 0 – 30% compression 60℃ 160 {16.3} or less 240 {24.5} or less Visual inspection under 0 – 30% compression The cap surface should not be broken. Elongation performance test Visual inspection in a 30% elongated state 20°C Disengagement should not occur at an elongation of 30%. Visual inspection in a 30% elongated state -20°C Disengagement should not occur at an elongation of 30%. Wear resistance test mg 20°C 1.000mg or less Heat shrinkage test Heat shrinkage % 20°C Shrinkage within 0.5% Visual inspection of “warpage” and “distortion” Every test specimen should be free from significant deformation Impact resistance test – 20°C Graded PD-3. Weather resistance test – 20°C Every test specimen should not be cracked.